Frame Size

|

-

3.35 in85 mm

|

Motor Length

|

-

5.51 in.140 mm

|

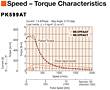

Speed-Torque Characteristics

|

-

Speed - Torque Characteristics

|

Holding Torque

|

-

580 oz-in4.1 N·m

|

Current per Phase (A/phase)

|

-

1.4

|

Type

|

-

Standard

|

Shaft/Gear Type

|

-

Round Shaft (No Gearhead)

|

Gear Type

|

-

No Gearhead

|

Motor Connection Type

|

-

Terminal Box

|

Shaft

|

-

Single

|

Basic Step Angle

|

-

0.72º

|

Output Step Angle

|

-

0.72 °

|

Connection Type

|

-

New Pentagon (Bipolar)

|

Lead Wires

|

-

5

|

Rotor Inertia

|

-

7.7 oz-in²1400x10-7 kg·m²

|

RoHS Compliant

|

-

Yes

|

Safety Standards

|

-

UL CSA EN CE

|

Insulation Resistance

|

-

100 MΩ minimum under normal temperature and humidity, when measured by a 500 VDC megger between the windings and the motor casing.

|

Dielectric Strength

|

-

Sufficient to withstand 1.5 kV, 50 Hz or 60 Hz applied for 1 minute between the windings and casing under normal temperature and humidity.

|

Temperature Rise

|

-

Temperature rise of the coil measured by the Change Resistance Method is 144ºF (80ºC) or less (at rated current, at standstill, five phases energized).

|

Insulation Class

|

-

Class B [266ºF (130ºC)] [Recognized as Class A 221ºF (105ºC) by UL standard]

|

Ambient Temperature Range

|

-

14ºF ~ 122ºF (-10ºC ~ 50ºC) (nonfreezing)

|

Ambient Humidity

|

-

85% or less (noncondensing)

|

Shaft Runout

|

-

0.002 in (0.05 mm) T.I.R.

|

Concentricity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Perpendicularity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Radial Play

|

-

0.001 inch (0.025 mm) max. of 1.12 lb. (5 N)

|

Axial Play

|

-

0.003 in (0.075 mm) max. of 2.2 lb. (10 N)

|

Radial Load

|

-

0 in. from Shaft End = 58 lb0.2 in. from Shaft End = 65 lb0.39 in. from Shaft End = 76 lb0.59 in. from Shaft End = 87 lb0.79 in. from Shaft End = 108 lb0 mm from Shaft End = 260 N5 mm from Shaft End = 290 N10 mm from Shaft End = 340 N15 mm from Shaft End = 390 N20 mm from Shaft End = 480 N

|

Axial Load

|

-

13.5 lb60 N

|