Busca de Manual e desenho 3D (CAD)

Para localizar o manual o desenho 3D (CAD) do produto digite o código do produto

As informações abaixo estão em inglês

The BLE2 Series features a a compact, high-power and high-efficiency brushless DC motor and is combined with an Driver that can be digitally set and controlled via external DC voltage or by the front panel. The entire motor structure features our latest brushless DC motor technology and has been innovated in pursuit of the optimal performance.

- IP67 Rated Motor

- Speed Control Range 80~4000 r/min

- Torque Limit Function

- The Driver can be Digitally Set and Controlled via the Front Panel.

Unit of Measure

| Lead Time1 | - {Contact your local sales office for more information.} |

Motor Frame Size |

- 4.33 in.110 mm |

Output Power |

- 200 W (1/4 HP) |

Power Supply |

- Single-Phase / Three-Phase 200-240 VAC |

Shaft/Gear Type |

- Parallel Shaft Gearhead (Stainless Steel Shaft) |

Gear Ratio (X:1) |

- 5 :1 |

Output Shaft Diameter |

- 22 mm |

Rated Torque |

- 25 lb-in2.9 N·m |

Electromagnetic Brake |

- Not Equipped |

Variable Speed Range (r/min) |

- 16 ~ 800 |

Permissible Load Inertia |

- 550 oz-in²*When instantaneous stop or instantaneous bi-directional operation is performed = 270 oz-in²100 x 10-4 kg·m²*When instantaneous stop or instantaneous bi-directional operation is performed = 50 x 10-4 kg·m² |

Permissible Radial Load |

- 0.39 in. from Shaft End = 123 lb0.79 in. from Shaft End = 180 lb10 mm from Shaft End = 550 N20 mm from Shaft End = 800 N |

Permissible Axial Load |

- 45 lb200 N |

Max. Extension Length |

- 20.5 m (65.6 ft.) |

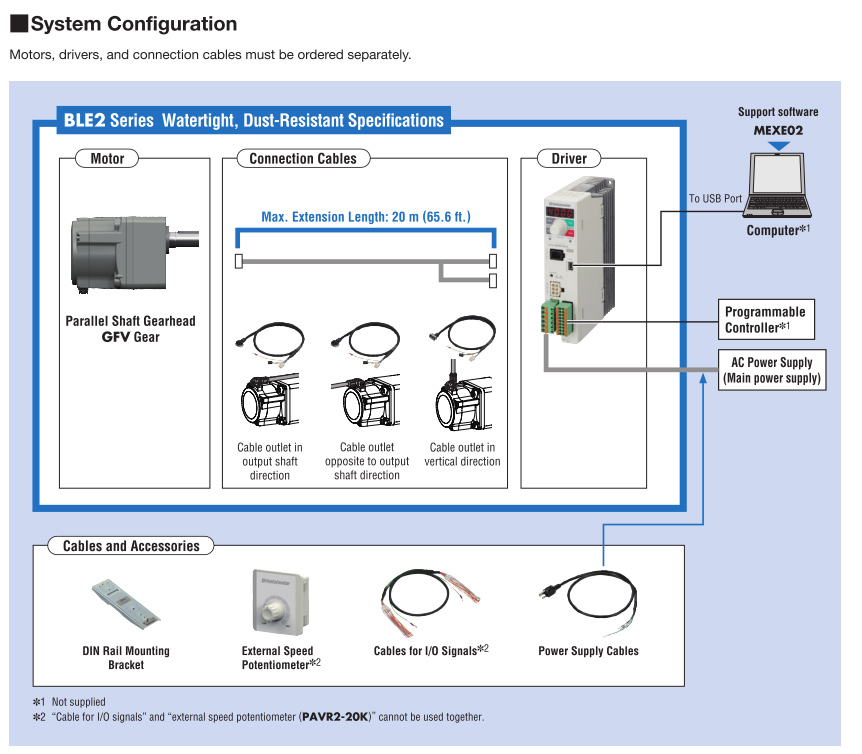

Components |

-

BLE2D200-C, Brushless DC Motor Driver (Single-Phase, Three-Phase 200-240 VAC) (Request Quote) BLM7200HW-GFV, 200 W (1/4 HP) BLM Series Brushless DC Pinion Shaft Motor () (Request Quote) GFV7G5SW, GFV Series IP67 Parallel Shaft Gearhead (5:1 Gear Ratio) (Request Quote) |

RoHS Compliant |

- These products do not contain substances that exceed the regulation values in the RoHS Directive. |

Safety Standards |

- UL CSA CE |

CE Marking |

- Low Voltage Directives EMC Directives |

Insulation Resistance (Motor) |

- 100 MΩ or more when 500 VDC megger is applied between the windings and the case after continuous operation under normal ambient temperature and humidity. |

Insulation Resistance (Driver) |

- 100 MΩ or more when a 500 VDC megger is applied between the power supply terminal and the protective earth terminal and between the power supply terminal and the I/O signal terminal after continuous operation under normal ambient temperature and humidity. |

Dielectric Strength (Motor) |

- Sufficient to withstand 1.5 kVAC at 50 Hz applied between the windings and the case for 1 minute after continuous operation under normal ambient temperature and humidity. |

Dielectric Strength (Driver) |

- Sufficient to withstand 1.5 kVAC at 50 Hz applied between the power supply terminal and the protective earth terminal for 1 minute and 1.5 kVAC at 50 Hz between the power supply terminal and the I/O terminal for 1 minute after continuous operation under normal ambient temperature and humidity. |

Temperature Rise (Motor) |

- The temperature rise of the windings is 90ºF (50ºC) and that of the case is 72ºF (40ºC) when measured by the thermocouple method after rated continuous operation under normal ambient temperature and humidity. |

Temperature Rise (Driver) |

- Temperature rise of the heat sink is 90ºF (50ºC) or less measured by the thermocouple method after rated continuous operation under normal ambient temperature and humidity. |

Ambient Temperature Range |

-

Motor: 32ºF ~ 104ºF (0ºC ~ 40ºC), nonfreezing Driver: 32ºF ~ 122ºF (0ºC ~ 50ºC) |

Ambient Humidity |

- 85% or less, noncondensing |

Altitude |

- Up to 3300 ft (1000 m) above sea level. |

Operating Atmosphere |

- No corrosive gases or dust. Cannot be used in a radioactive area, magnetic field, vacuum or other special environment. |

Thermal Class |

- CSA standards: 105 (A), EN standards: 120 (E) UL |

Degree of Protection |

-

Motor: IP67 Driver: IP20 |

Speed Control Method (Select one of the following) |

-

Digital Setting:

Analog Setting:

|

Number of Speed Settings |

- Max. 16 points (Factory setting: 4 points) |

Acceleration/Deceleration Time |

- 0.0 ~ 15.0 s (Factory setting: 0.5 s) |

Torque Limiting |

-

0~300% (Factory Setting: 300%) Digital Setting:

|

Input Signals |

-

Photocoupler Input Input Resistance: 6.6 kΩ Connectable External DC Power Supply: 24 VDC -15 ~ +20% Current 100 mA min. Sink Input/Source Input Supports External Wiring Arbitrary signal assignment to IN0 ~ IN6 input (7 points) is possible. [ ]: Initial Setting [FWD], [REV], [STOP-MODE], [M0], [M1], [ALARM-RESET], [Not Used], M2, M3, H-FREE, TL, INFO-CLR, HMI, EXT-ERROR, START/STOP, RUN/BRAKE, CW/CWW |

Output Signals |

-

Photocoupler and Open-Collector Output (ON Power supply: 1.6 V max.) External Power Supply: 4.5 ~ 30 V 100 mA max. (5 mA min. for SPEED-OUT output) Sink Output/Source Output Supported through external wiring Arbitrary signal assignment to OUT0, OUT1 (2 points) is possible. [ ]: Initial setting [SPEED-OUT], [ALARM-OUT], MOVE, INFO, TLC, VA, DIR |

Protective Function |

-

When the following protective functions are activated, the output from ALARM-OUT will turn OFF and the motor will perform a coasting stop. At the same time, the alarm code will be displayed and the Alarm LED flashes red. Overcurrent, main circuit overheat, overvoltage, undervoltage, sensor error, main circuit output error, overload, over-speed, EEPROM error, initial sensor error, initial operation prohibited, external stop |

Time Rating |

- Continuous |

|

|

|

|

|

|

|

|

- 1 Quoted Ship Date for orders placed before 12:00 pm PST. Quantities may affect Shipping Date.