Motores sin Escobillas

- Motores sin Escobillas Sistemas de Control de Velocidad CA

- Motores sin Escobillas Sistemas de Control de Velocidad CC

Atuadores Lineares

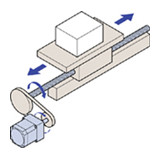

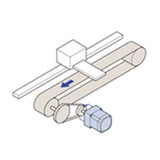

- Atuadores Lineares - Guías Lineales Motorizadas

- Atuadores Lineares - Cilindros Lineales Motorizados

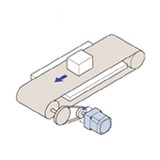

- Atuadores Lineares Compactos

- Atuadores Lineares (Actuadores Únicamente)

- Controladores / Productos de Red

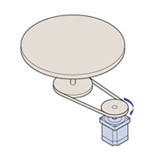

Actuadores Hiratorios Huecos

CAD / Búsqueda Manual

Para encontrar CAD y Manuales de Operador de nuestros products, por favor realice la búsqueda usando el número de item

![]()

Para Inglés o Español:

Para japonés:

Clientes de Mexíco:

Servicio Al Cliente - +001-847-871-5931

Soporte técnico - 800-681-5309

Clientes Internacionales:

+1-847-871-5931 o

+1-310-715-3304

Para soporte en productos del catálogo japonés:

1-800-746-6872 o

+1-310-715-3304

Specifications

Motor Type |

- Brushless DC Motor |

Motor Frame Size |

- 3.15 in.80 mm |

Output Power |

- 60 W (1/12 HP) |

Power Supply |

- Single-Phase 100-115 VAC |

Shaft/Gear Type |

- Parallel Shaft Gearhead |

Gear Ratio (X:1) |

- 50 :1 |

Output Shaft Diameter |

- 15 mm |

Rated Torque |

- 76 lb-in8.6 N·m |

Electromagnetic Brake |

- Equipped |

Control Module Included |

- No |

Variable Speed Range (r/min) |

- 0.6 ~ 60 |

Permissible Load Inertia |

- 12000 oz-in²2200 x 10-4 kg·m² |

Permissible Overhung Load |

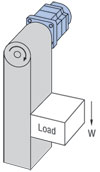

- 0.39 in. from Shaft End = 101 lb0.79 in. from Shaft End = 123 lb10 mm from Shaft End = 450 N20 mm from Shaft End = 550 N |

Permissible Thrust Load |

- 22 lb100 N |

Alarm Output |

- Yes |

Position Control Mode |

- No |

Vertical Drive (Gravitational Operation) |

- Yes |

Max. Extension Length (m) |

- 20 |

Components |

- BXM460M-GFS (Motor) BXD60A-A (Driver) GFS4G50 (Gearhead) |

RoHS Compliant |

- Yes |

Safety Standards |

- UL CSA EN CE |

CE Marking |

- Low Voltage Directives EMC Directives |

Insulation Class |

-

[Motor] UL, CSA standards: Class A (221ºF [105ºC]) EN standards: Class E (248ºF [120ºC]) |

Insulation Resistance (Motor) |

- 100 MΩ or more when 500 VDC megger is applied between the windings and the case after continuous operation under normal ambient temperature and humidity (except for encoder). |

Insulation Resistance (Driver) |

- 100 M Ω or more when 500 VDC megger is applied between the power supply input terminal and the case, and between the power supply input terminal and the I/O terminal after continuous operation under normal ambient temperature and humidity. |

Dielectric Strength (Motor) |

- Sufficient to withstand 1.5 kVAC at 50 Hz applied between the windings and the case for 1 minute after continuous operation under normal ambient temperature and humidity (except for encoder). |

Dielectric Strength (Driver) |

- Sufficient to withstand 1.5 kVAC, 50 Hz applied between case and power supply input for 1 min. and 1.8 kVAC, 50 Hz applied between power supply input and the I/O terminal for 1 min. after continuous operation under normal ambient temperature and humidity. |

Control System |

- PWM Control |

Control Detection System |

- Optical Encoder (500 P/R) |

Ambient Temperature Range |

- 32ºF ~ 122ºF (0ºC ~ 50ºC), nonfreezing |

Ambient Humidity |

- 85% maximum, noncondensing |

Operating Atmosphere |

- No corrosive gases or dust. Use in a radioactive or magnetic field, vacuum or any other special environment is prohibited. |

Brake Specifications

Brake Type |

- Active when the power is off, automatically controlled by the driver. |

Static Friction Torque |

- 28 oz-in |

Speed Control Features

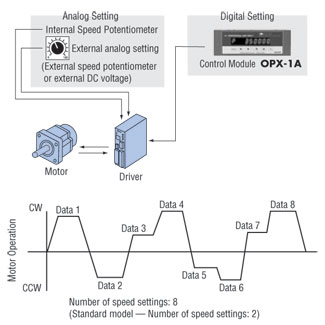

Speed Control Method (Select one of the following) |

- Internal potentiometer External DC voltage External potentiometer (20kΩ, 1/4W) |

Number of Speed Settings |

- 2 |

Multi-Speed Setting Method |

- 1 speed set by the internal speed potentiometer and 1 speed set by the external speed potentiometer (20 kΩ, 1/4 W) or external DC voltage (0 ~ 5 VDC) |

Instantaneous Stop |

- Yes |

Multi-Axes Control |

- Yes |

Product Features

|

-

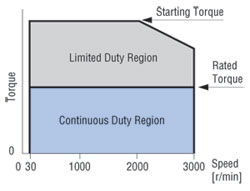

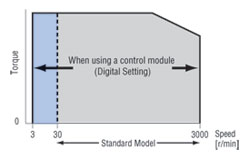

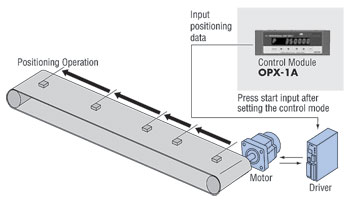

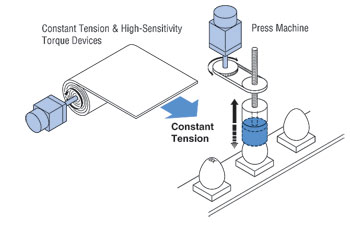

The BX Series offers a wide speed range of 30 to 3000 r/min and provides flat torque at all speeds from high to low. The high starting torque characteristics ensure ample torque at start and stop. The BX Series offers highly accurate speed control, achieving an excellent speed regulation with respect to load. Speed Regulation: With the BX Series, rotational irregularity at medium and high speeds is also reduced substantially. The motor with an electromagnetic brake enables stable speed control even during vertical drive (gravitational operation). When the power is turned off, the motor stops instantly to hold the load in place. The electromagnetic brake is automatically controlled via the driver in accordance with ON/OFF of the operation command signal. You can extend the functions of the BX Series using an optional control module (OPX-1A). The following functions are available on the extended system: Speed can be set digitally using an optional control module. You can set up to eight different speeds. The digital speed setting function expands the speed control range to cover 3 to 3000 r/min. Improved Speed Control Accuracy When using a control module (Digital Setting): Position control can be performed with the BX Series simply by setting data using the optional control module. The resolution is 0.72° (500 pulses per rotation) and a maximum of six points of positioning data can be set, of which two can be set for continuous operation. Return to mechanical/electrical home operation can also be performed. Use of the optional control module enables torque limiting. The torque limiting function suppresses the motor output torque in accordance with the application and use condition. The high-strength gearhead is designed to withstand high-speed revolutions. The rated life of the gearhead is 10000 hours, which is twice as long as that of our previous gearhead. |

Wide Speed Control Range and Flat Torque

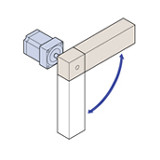

Wide Speed Control Range and Flat Torque  Speed Control During Vertical Drive

Speed Control During Vertical Drive Control Module OPX-1A (sold separately)

Control Module OPX-1A (sold separately)  Digital Speed Setting up to Eight Speeds (Extended Function Using Control Module)

Digital Speed Setting up to Eight Speeds (Extended Function Using Control Module) Speed Control Range of 3 to 3000 r/min (Extended Function Using Control Module)

Speed Control Range of 3 to 3000 r/min (Extended Function Using Control Module) Position Control (Extended Function Using Control Module)

Position Control (Extended Function Using Control Module) Torque Limiting (Extended Function Using Control Module)

Torque Limiting (Extended Function Using Control Module) Long-Life Parallel Shaft Gearhead

Long-Life Parallel Shaft Gearhead