Motores sin Escobillas

- Motores sin Escobillas Sistemas de Control de Velocidad CA

- Motores sin Escobillas Sistemas de Control de Velocidad CC

Atuadores Lineares

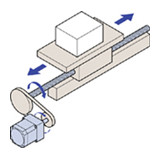

- Atuadores Lineares - Guías Lineales Motorizadas

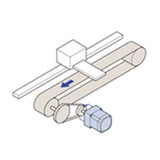

- Atuadores Lineares - Cilindros Lineales Motorizados

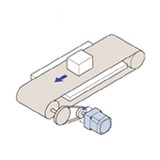

- Atuadores Lineares Compactos

- Atuadores Lineares (Actuadores Únicamente)

- Controladores / Productos de Red

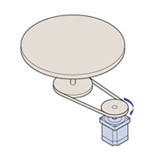

Actuadores Hiratorios Huecos

CAD / Búsqueda Manual

Para encontrar CAD y Manuales de Operador de nuestros products, por favor realice la búsqueda usando el número de item

![]()

Para Inglés o Español:

Para japonés:

Clientes de Mexíco:

Servicio Al Cliente - +001-847-871-5931

Soporte técnico - 800-681-5309

Clientes Internacionales:

+1-847-871-5931 o

+1-310-715-3304

Para soporte en productos del catálogo japonés:

1-800-746-6872 o

+1-310-715-3304

Compatible Motors (sold separately)

Specifications

Features

|

-

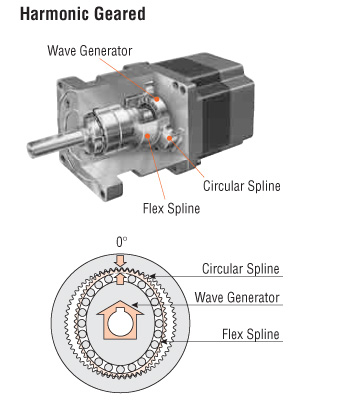

The PK Series 0.72°stepping motor offers high torque, our lowest vibration and noise. This motor is wound in the bipolar New Pentagon configuration and therefore, require a New Pentagon bipolar type driver. The New Pentagon configuration ensures that maximum torque is being generated by the motor on every step. The New Pentagon configuration also provides extremely smooth motion as well as maintaining torque and step accuracy regardless of the step resolution. The harmonic gear offers unparalleled precision in positioning and features a simple construction utilizing the metal's elastomechanical property, comprising just three basic components: a wave generator, flex spline and circular spline. Available in 0.79 in. (20mm), 1.65 in. (42mm), 2.36 in. (60mm) and 3.54 in. (90mm) frame sizes. Combines three basic parts. The flex spline is bent into an oval shape by the wave generator. The teeth at the long axis of the oval mesh with the circular spline, while the teeth at the short axis of the oval are completely separate from it. The PK Series stepping motor with encoder offers high torque and precise feedback capability. |

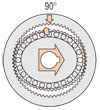

Rotating the wave generator (input) clockwise while keeping the circular spline fixed in position will subject the flax spline to elastic deformation, causing a gradual shift in the point of engagement between the circular spline and flex spline.

Rotating the wave generator (input) clockwise while keeping the circular spline fixed in position will subject the flax spline to elastic deformation, causing a gradual shift in the point of engagement between the circular spline and flex spline. When the wave generator completes one revolution, the flex spline has rotated two fewer teeth than the circular spline has, resulting in the movement of the flex spline for the difference in the tooth count (two teeth) in the opposite direction of the wave generator's rotation (i.e. counterclockwise). This movement translates into output, thereby reducing the speed.

When the wave generator completes one revolution, the flex spline has rotated two fewer teeth than the circular spline has, resulting in the movement of the flex spline for the difference in the tooth count (two teeth) in the opposite direction of the wave generator's rotation (i.e. counterclockwise). This movement translates into output, thereby reducing the speed. Encoder Option Available

Encoder Option Available