|

Lead Time1

|

-

{Contact your local sales office for more information.}

|

Frame Size

|

-

1.65 in42 mm

|

Motor Length

|

-

5.35 in.136 mm

|

Driver Voltage Input Power

|

-

DC

|

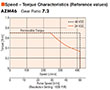

Speed-Torque Characteristics

|

-

|

Holding Torque

|

-

99 oz-in0.7 N·m

|

Holding Torque at Motor Standstill

|

-

99 oz-in0.7 N·m

|

Type

|

-

Mechanical Absolute Encoder

|

Shaft/Gear Type

|

-

Right-Angle Spur / Face Gear

|

Gear Ratio (X:1)

|

-

7.2 :1

|

Backlash

|

-

25 arc min (0.42°)

|

Shaft

|

-

Single

|

Electromagnetic Brake

|

-

Not Equipped

|

Resolution (Resolution Setting: 1000 P/R)

|

-

0.05 °/Pulse

|

Permissible Speed Range (r/min)

|

-

0 ~ 416

|

Rotor Inertia

|

-

0.3 oz-in²55x10-7 kg·m²

|

Stop Position Accuracy

|

-

±4 arc minutes (±0.067º)

|

Shaft Runout

|

-

0.05 mm (0.002 in.) T.I.R.

|

Concentricity

|

-

0.075 mm (0.003 in.) T.I.R.

|

Perpendicularity

|

-

0.075 mm (0.003 in.) T.I.R.

|

Permissible Overhung Load

|

-

0 in. from Shaft End = 40 lb0.2 in. from Shaft End = 45 lb0.39 in. from Shaft End = 49 lb0.59 in. from Shaft End = 56 lb0 mm from Shaft End = 180 N5 mm from Shaft End = 200 N10 mm from Shaft End = 220 N15 mm from Shaft End = 250 N

|

Permissible Thrust Load

|

-

22 lb100 N

|

RoHS Compliant

|

-

These products do not contain substances that exceed the regulation values in the RoHS Directive.

|

Safety Standards

|

-

UL CE

|

CE Marking

|

-

EMC Directives

|

California Proposition 65

|

-

⚠ CA WARNING

Cancer risk from exposure to Nickel. See www.P65Warnings.ca.gov

Risk of reproductive harm from exposure to Di-n-hexyl phthalate (DnHP). See www.P65Warnings.ca.gov

Risk of cancer and reproductive harm from exposure to Di(2-ethylhexyl phthalate (DEHP). See www.P65Warnings.ca.gov

See "?" or copy/paste www.P65Warnings.ca.gov in your browser.

|

Insulation Class

|

-

Class B [130ºC (266ºF)]

|

Insulation Resistance

|

-

100 MΩ or more when 500 VDC megger is applied between the following places:

Case - Motor and sensor windings

|

Dielectric Strength

|

-

Sufficient to withstand the following for 1 minute:

Case - Motor and sensor windings 1.5 kVAC 50 Hz or 60 Hz

|

Ambient Temperature

|

-

0 ~ 40ºC (32 ~ 104ºF) (non-freezing)

|

Ambient Humidity

|

-

85% or less (Non-condensing)

|

Operating Atmosphere

|

-

Use in an area without corrosive gases and dust. The product should not be exposed to water, oil or other liquids.

|

Degree of Protection

|

-

IP66 when connecting the connection cable (excluding the mounting surface and connector on the driver side of the connection cable)

|

![]()