ORIENTAL MOTOR U.S.A. Corp.

570 Alaska Avenue

Torrance, CA 90503

1-800-GO-VEXTA (468-3982)

ORIENTAL MOTOR U.S.A. Corp.

570 Alaska Avenue

Torrance, CA 90503

1-800-GO-VEXTA (468-3982)

| Items |

RK543AA Microstep Stepper Motor System (Single-Phase 100-115 VAC) Web Price Request Quote

|

RK543BA Microstep Stepper Motor System (Single-Phase 100-115 VAC) Web Price Request Quote

|

RK543AA-T3.6 Microstep Stepper Motor System (Single-Phase 100-115 VAC) Web Price Request Quote

|

RK543AA-T7.2 Microstep Stepper Motor System (Single-Phase 100-115 VAC) Web Price Request Quote

|

RK543AA-T10 Microstep Stepper Motor System (Single-Phase 100-115 VAC) Web Price Request Quote

|

|||||

| Frame Size | - 1.65 in | |||||||||

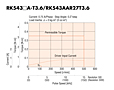

| Speed-Torque Characteristics |

-

Graph |

-

Graph |

-

Graph |

-

Graph |

-

Graph |

|||||

| Holding Torque | - 18.4 oz-in | - 18.4 oz-in | - 48 oz-in | - 98 oz-in | - 141 oz-in | |||||

| Type | - Standard | - Standard | - Geared | - Geared | - Geared | |||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Taper Hobbed Gear | - Taper Hobbed Gear | - Taper Hobbed Gear | |||||

| Gear Ratio (X:1) | - | - | - 3.6 :1 | - 7.2 :1 | - 10 :1 | |||||

| Backlash | - | - | - 2 arc min (0.034º) | - 10 arc min (0.17º) | - 10 arc min (0.17º) | |||||

| Shaft | - Single | - Double | - Single | - Single | - Single | |||||

| Power Supply | - Single-Phase 100-115 VAC | |||||||||

| Current | - 0.75 A | |||||||||

| Basic Step Angle | - Microstep- 0.00288º ~ 0.72º | - Microstep- 0.00288º ~ 0.72º | - Microstep- 0.0008º ~ 0.2º | - Microstep- 0.0004º ~ 0.1º | - Microstep- 0.000288º ~ 0.072º | |||||

| Permissible Speed Range (r/min) | - | - | - 0 ~ 500 | - 0 ~ 250 | - 0 ~ 180 | |||||

| Rotor Inertia | - 0.191 oz-in² | |||||||||

| Lost Motion | - | |||||||||

| Encoder Output | - | |||||||||

| Safety Standards | - UL CSA (driver only) EN CE | |||||||||

| Permissible Overhung Load | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 5.6 lb0.39 in. from Shaft End = 7.6 lb0.59 in. from Shaft End = 11.7 lb | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 5.6 lb0.39 in. from Shaft End = 7.6 lb0.59 in. from Shaft End = 11.7 lb | - 0 in. from Shaft End = 2.2 lb0.2 in. from Shaft End = 3.1 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 6.7 lb | - 0 in. from Shaft End = 2.2 lb0.2 in. from Shaft End = 3.1 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 6.7 lb | - 0 in. from Shaft End = 2.2 lb0.2 in. from Shaft End = 3.1 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 6.7 lb | |||||

| Permissible Thrust Load | - | - | - 3.3 lb | - 3.3 lb | - 3.3 lb | |||||

| Permissible Thrust Load | - The permissible thrust load shall be no greater than the motor mass. | - The permissible thrust load shall be no greater than the motor mass. | - | - | - | |||||

| Current per Phase (A/phase) | - | |||||||||

| Motor Connection Type | - | |||||||||

| Connection Type | - | |||||||||

| Lead Wires | - | |||||||||

| Lead Time (Legacy) | - | |||||||||

|

|

||||||||||