The PKP series 5-phase stepper motor offers balanced performance enhanced by high torque, low vibration and low noise.

| Items |

PKP544MN18A 1.65 in. (42 mm) PKP Series 5-Phase Stepper Motor Web Price $65.00

|

PKP544MN18B 1.65 in. (42 mm) PKP Series 5-Phase Stepper Motor Web Price $66.00

|

PKP546MN18A 1.65 in. (42 mm) PKP Series 5-Phase Stepper Motor Web Price $75.00

|

PKP546MN18B 1.65 in. (42 mm) PKP Series 5-Phase Stepper Motor Web Price $77.00

|

PKP543N18A2 1.65 in. (42 mm) PKP Series 5-Phase Stepper Motor Web Price $69.00

|

|||||

| Frame Size | - 1.65 in42 mm | |||||||||

| Motor Length | - 1.54 in.39 mm | - 1.54 in.39 mm | - 2.32 in.59 mm | - 2.32 in.59 mm | - 1.3 in.33 mm | |||||

| Basic Step Angle | - 0.36º | - 0.36º | - 0.36º | - 0.36º | - 0.72º | |||||

| Step Angle | - 0.36 ° | - 0.36 ° | - 0.36 ° | - 0.36 ° | - 0.72 ° | |||||

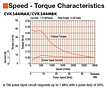

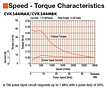

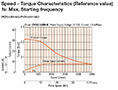

| Speed-Torque Characteristics |

-

|

-

|

-

|

-

|

-

|

|||||

|

Holding Torque |

- 36 oz-in0.26 N·m | - 36 oz-in0.26 N·m | - 62 oz-in0.44 N·m | - 62 oz-in0.44 N·m | - 31 oz-in0.22 N·m | |||||

| Current per Phase | - 1.8 A/phase | |||||||||

| Type | - High-Resolution | - High-Resolution | - High-Resolution | - High-Resolution | - Standard | |||||

| Shaft/Gear Type | - Round Shaft with Flat (No Gearhead) | |||||||||

| Gear Ratio (X:1) | - | |||||||||

| Backlash | - | |||||||||

| Encoder | - Not Equipped | |||||||||

| Output Type | - | |||||||||

| Motor Connection Type | - Connector | - Connector | - Connector | - Connector | - Flat Connector | |||||

| Electromagnetic Brake | - Not Equipped | |||||||||

| Shaft | - Single | - Double | - Single | - Double | - Single | |||||

| Output Shaft | - Metric | |||||||||

| Output Shaft Diameter | - 5 mm | |||||||||

| Connection Type | - New Pentagon (Bipolar) | |||||||||

| Lead Wires | - 5 | |||||||||

| Rotor Inertia | - 0.33 oz-in²60x10-7 kg·m² | - 0.33 oz-in²60x10-7 kg·m² | - 0.66 oz-in²121x10-7 kg·m² | - 0.66 oz-in²121x10-7 kg·m² | - 0.192 oz-in²35x10-7 kg·m² | |||||

| Lost Motion | - | |||||||||

| Static Friction Torque | - | |||||||||

| Radial Load | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 5.6 lb0.39 in. from Shaft End = 7.6 lb0.59 in. from Shaft End = 11.7 lb0 mm from Shaft End = 20 N5 mm from Shaft End = 25 N10 mm from Shaft End = 34 N15 mm from Shaft End = 52 N | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 5.6 lb0.39 in. from Shaft End = 7.6 lb0.59 in. from Shaft End = 11.7 lb0 mm from Shaft End = 20 N5 mm from Shaft End = 25 N10 mm from Shaft End = 34 N15 mm from Shaft End = 52 N | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 5.6 lb0.39 in. from Shaft End = 7.6 lb0.59 in. from Shaft End = 11.7 lb0 mm from Shaft End = 20 N5 mm from Shaft End = 25 N10 mm from Shaft End = 34 N15 mm from Shaft End = 52 N | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 5.6 lb0.39 in. from Shaft End = 7.6 lb0.59 in. from Shaft End = 11.7 lb0 mm from Shaft End = 20 N5 mm from Shaft End = 25 N10 mm from Shaft End = 34 N15 mm from Shaft End = 52 N | - 0 in. from Shaft End = 7.9 lb0.2 in. from Shaft End = 9.9 lb0.39 in. from Shaft End = 13.0 lb0.59 in. from Shaft End = 19.1 lb0 mm from Shaft End = 35 N5 mm from Shaft End = 44 N10 mm from Shaft End = 58 N15 mm from Shaft End = 85 N | |||||

| Axial Load | - 2.2 lb10 N | - 2.2 lb10 N | - 2.2 lb10 N | - 2.2 lb10 N | - 3.4 lb15 N | |||||

| Permissible Moment Load | - | |||||||||

|

RoHS Compliant |

- These products do not contain substances that exceed the regulation values in the RoHS Directive. | |||||||||

|

Safety Standards |

- CE | |||||||||

|

|

||||||||||