The AR Series substantially reduces heat generation from the motor allowing for continuous operation. In addition to implementing the closed loop control based on Oriental Motor's original Alpha Step technology, with the AR Series there is no gain tuning or hunting problems. Based on stepping motor technology the AR Series can perform quick positioning operations over a short distance while providing smooth performance and consumes up to 40% less power than conventional models.

| Items |

AR24SAK-3 AlphaStep Closed Loop Stepper Motor and Driver Web Price Request Quote

|

AR24SBK-3 AlphaStep Closed Loop Stepper Motor and Driver Web Price Request Quote

|

AR26SAK-3 AlphaStep Closed Loop Stepper Motor and Driver Web Price Request Quote

|

AR26SBK-3 AlphaStep Closed Loop Stepper Motor and Driver Web Price Request Quote

|

AR24SAK-T7.2-3 AlphaStep Closed Loop Stepper Motor and Driver Web Price Request Quote

|

|||||

| Frame Size | - 1.1 in28 mm | |||||||||

| Motor Length | - 1.77 in.45 mm | - 1.77 in.45 mm | - 2.56 in.65 mm | - 2.56 in.65 mm | - 2.78 in.70.5 mm | |||||

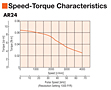

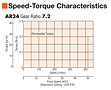

| Speed-Torque Characteristics |

-

Speed - Torque Characteristics |

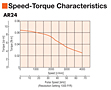

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

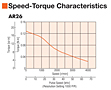

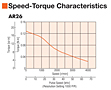

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

|||||

|

Holding Torque |

- 7.8 oz-in0.055 N·m | - 7.8 oz-in0.055 N·m | - 17 oz-in0.12 N·m | - 17 oz-in0.12 N·m | - 28 oz-in0.2 N·m | |||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Taper Hobbed Gear | |||||

| Gear Ratio (X:1) | - | - | - | - | - 7.2 :1 | |||||

| Backlash | - | - | - | - | - 60 arc min (1°) | |||||

| Electromagnetic Brake | - Not Equipped | |||||||||

|

Static Friction Torque |

- | |||||||||

|

Shaft |

- Single | - Double | - Single | - Double | - Single | |||||

| Power Supply | - 24 VDC | |||||||||

|

Current |

- 0.9 A | |||||||||

| Permissible Speed Range (r/min) | - | - | - | - | - 0 ~ 416 | |||||

| Rotor Inertia | - 0.06 oz-in²11x10-7 kg·m² | - 0.06 oz-in²11x10-7 kg·m² | - 0.109 oz-in²20x10-7 kg·m² | - 0.109 oz-in²20x10-7 kg·m² | - 0.06 oz-in²11x10-7 kg·m² | |||||

| Lost Motion | - | |||||||||

|

RoHS Compliant |

- Yes | |||||||||

|

Safety Standards |

- CE | |||||||||

| Radial Load | - 0 in. from Shaft End = 5.6 lb0.2 in. from Shaft End = 7.6 lb0.39 in. from Shaft End = 11.7 lb0 mm from Shaft End = 25 N5 mm from Shaft End = 34 N10 mm from Shaft End = 52 N | - 0 in. from Shaft End = 5.6 lb0.2 in. from Shaft End = 7.6 lb0.39 in. from Shaft End = 11.7 lb0 mm from Shaft End = 25 N5 mm from Shaft End = 34 N10 mm from Shaft End = 52 N | - 0 in. from Shaft End = 5.6 lb0.2 in. from Shaft End = 7.6 lb0.39 in. from Shaft End = 11.7 lb0 mm from Shaft End = 25 N5 mm from Shaft End = 34 N10 mm from Shaft End = 52 N | - 0 in. from Shaft End = 5.6 lb0.2 in. from Shaft End = 7.6 lb0.39 in. from Shaft End = 11.7 lb0 mm from Shaft End = 25 N5 mm from Shaft End = 34 N10 mm from Shaft End = 52 N | - 0 in. from Shaft End = 3.3 lb0.2 in. from Shaft End = 3.8 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 5.1 lb0 mm from Shaft End = 15 N5 mm from Shaft End = 17 N10 mm from Shaft End = 20 N15 mm from Shaft End = 23 N | |||||

| Axial Load | - 1.1 lb5 N | - 1.1 lb5 N | - 1.1 lb5 N | - 1.1 lb5 N | - 2.2 lb10 N | |||||

| Control Power Supply | - | |||||||||

| UPC Code | - | |||||||||

|

|

||||||||||