| Items |

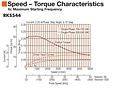

RKS543AA Microstep Stepper Motor & Driver Web Price Request Quote

|

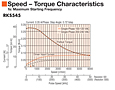

RKS544AA Microstep Stepper Motor & Driver Web Price Request Quote

|

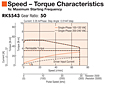

RKS545AA Microstep Stepper Motor & Driver Web Price Request Quote

|

RKS543AA-HS50 Microstep Stepper Motor & Driver Web Price Request Quote

|

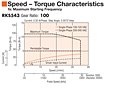

RKS543AA-HS100 Microstep Stepper Motor & Driver Web Price Request Quote

|

|||||

| Frame Size | - 1.65 in42 mm | |||||||||

| Motor Length | - 1.34 in.34 mm | - 1.57 in.40 mm | - 1.81 in.46 mm | - 1.34 in.34 mm | - 1.34 in.34 mm | |||||

| Speed-Torque Characteristics |

-

|

-

|

-

|

-

|

-

|

|||||

|

Holding Torque |

- 19.80 oz-in0.14 N·m | - 29 oz-in0.21 N·m | - 38 oz-in0.27 N·m | - 480 oz-in3.50 N·m | - 704 oz-in5 N·m | |||||

| Type | - Standard | - Standard | - Standard | - Geared | - Geared | |||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Harmonic Gear | - Harmonic Gear | |||||

| Gear Ratio (X:1) | - | - | - | - 50 :1 | - 100 :1 | |||||

| Backlash | - | |||||||||

| Shaft | - Single | |||||||||

| Electromagnetic Brake | - Not Equipped | |||||||||

| Power Supply | - Single-Phase 100-120 VAC | |||||||||

| Current | - 2.1 A | - 1.9 A | - 1.9 A | - 2.1 A | - 2.1 A | |||||

| Basic Step Angle | - 0.72º | - 0.72º | - 0.72º | - 0.0144º | - 0.0072º | |||||

| Permissible Speed Range (r/min) | - | - | - | - 0 ~ 70 | - 0 ~ 35 | |||||

| Rotor Inertia | - 0.16 oz-in²30x10-7 kg·m² | - 0.26 oz-in²47x10-7 kg·m² | - 0.35 oz-in²64x10-7 kg·m² | - 0.26 oz-in²47x10-7 kg·m² | - 0.26 oz-in²47x10-7 kg·m² | |||||

| Lost Motion | - | - | - | - 1.5 arc min maximum | - 1.5 arc min maximum | |||||

| Radial Load | - 0 in. from Shaft End = 7.8 lb0.2 in. from Shaft End = 9.9 lb0.39 in. from Shaft End = 13 lb0.59 in. from Shaft End = 19.1 lb0 mm from Shaft End = 35 N5 mm from Shaft End = 44 N10 mm from Shaft End = 58 N15 mm from Shaft End = 85 N | - 0 in. from Shaft End = 7.8 lb0.2 in. from Shaft End = 9.9 lb0.39 in. from Shaft End = 13 lb0.59 in. from Shaft End = 19.1 lb0 mm from Shaft End = 35 N5 mm from Shaft End = 44 N10 mm from Shaft End = 58 N15 mm from Shaft End = 85 N | - 0 in. from Shaft End = 7.8 lb0.2 in. from Shaft End = 9.9 lb0.39 in. from Shaft End = 13 lb0.59 in. from Shaft End = 19.1 lb0 mm from Shaft End = 35 N5 mm from Shaft End = 44 N10 mm from Shaft End = 58 N15 mm from Shaft End = 85 N | - 0 in. from Shaft End = 40 lb0.2 in. from Shaft End = 49 lb0.39 in. from Shaft End = 60 lb0.59 in. from Shaft End = 81 lb0.79 in. from Shaft End = 114 lb0 mm from Shaft End = 180 N5 mm from Shaft End = 220 N10 mm from Shaft End = 270 N15 mm from Shaft End = 360 N20 mm from Shaft End = 510 N | - 0 in. from Shaft End = 40 lb0.2 in. from Shaft End = 49 lb0.39 in. from Shaft End = 60 lb0.59 in. from Shaft End = 81 lb0.79 in. from Shaft End = 114 lb0 mm from Shaft End = 180 N5 mm from Shaft End = 220 N10 mm from Shaft End = 270 N15 mm from Shaft End = 360 N20 mm from Shaft End = 510 N | |||||

| Axial Load | - 3.3 lb15 N | - 3.3 lb15 N | - 3.3 lb15 N | - 49 lb220 N | - 49 lb220 N | |||||

| Encoder Output | - | |||||||||

|

Safety Standards |

- UL CE | |||||||||

|

|

||||||||||