ORIENTAL MOTOR U.S.A. Corp.

570 Alaska Avenue

Torrance, CA 90503

1-800-GO-VEXTA (468-3982)

ORIENTAL MOTOR U.S.A. Corp.

570 Alaska Avenue

Torrance, CA 90503

1-800-GO-VEXTA (468-3982)

| Items |

AS46MAP AlphaStep Closed Loop Stepper Motor and Driver with Built-in Controller |

AS46AAP AlphaStep Closed Loop Stepper Motor and Driver with Built-in Controller |

AS46MAP-T3.6 AlphaStep Closed Loop Stepper Motor and Driver with Built-in Controller |

AS46MAP-T7.2 AlphaStep Closed Loop Stepper Motor and Driver with Built-in Controller |

AS46MAP-T10 AlphaStep Closed Loop Stepper Motor and Driver with Built-in Controller |

|||||

| Frame Size | - 1.65 in | |||||||||

| Motor Length | - 3.74 in. | - 2.56 in. | - 4.94 in. | - 4.94 in. | - 4.94 in. | |||||

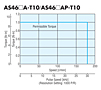

| Speed-Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

|||||

| Holding Torque | - 42 oz-in | - 42 oz-in | - 48 oz-in | - 97.6 oz-in | - 140.8 oz-in | |||||

| Type | - Standard | |||||||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Taper Hobbed Gear | - Taper Hobbed Gear | - Taper Hobbed Gear | |||||

| Gear Ratio (X:1) | - | - | - 3.6 :1 | - 7.2 :1 | - 10 :1 | |||||

| Backlash | - | - | - 2 arc min (0.034º) | - 10 arc min (0.167º) | - 10 arc min (0.167º) | |||||

| Electromagnetic Brake | - Equipped | - Not Equipped | - Equipped | - Equipped | - Equipped | |||||

| Static Friction Torque | - 1.3125 lb-in | - | - 1.5 lb-in | - 3 lb-in | - 4.4 lb-in | |||||

| Continuous Duty | - No | |||||||||

| Closed Loop System | - Yes | |||||||||

| Built-in Controller | - Yes | |||||||||

| Smooth Drive Function | - No | |||||||||

| Shaft | - Single | |||||||||

| Power Supply | - Single-Phase 100-115 VAC | |||||||||

| Current | - 3.3 A | |||||||||

| Permissible Speed Range (r/min) | - | - | - 0 ~ 500 | - 0 ~ 250 | - 0 ~ 180 | |||||

| Rotor Inertia | - 0.45 oz-in² | - 0.37 oz-in² | - 0.45 oz-in² | - 0.45 oz-in² | - 0.45 oz-in² | |||||

| Lost Motion | - | |||||||||

| RoHS Compliant | - Yes | |||||||||

| Safety Standards | - UL CSA (driver only) EN CE | |||||||||

| Permissible Overhung Load | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 5.6 lb0.39 in. from Shaft End = 7.6 lb0.59 in. from Shaft End = 11.7 lb | - 0 in. from Shaft End = 4.5 lb0.2 in. from Shaft End = 5.6 lb0.39 in. from Shaft End = 7.6 lb0.59 in. from Shaft End = 11.7 lb | - 0 in. from Shaft End = 2.2 lb0.2 in. from Shaft End = 3.1 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 6.7 lb | - 0 in. from Shaft End = 2.2 lb0.2 in. from Shaft End = 3.1 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 6.7 lb | - 0 in. from Shaft End = 2.2 lb0.2 in. from Shaft End = 3.1 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 6.7 lb | |||||

| Permissible Thrust Load | - | - | - 3.3 lb | - 3.3 lb | - 3.3 lb | |||||

| Permissible Thrust Load | - The permissible thrust load shall be no greater than the motor mass. | - The permissible thrust load shall be no greater than the motor mass. | - | - | - | |||||

| List Price | - | |||||||||

|

|

||||||||||