ORIENTAL MOTOR U.S.A. Corp.

570 Alaska Avenue

Torrance, CA 90503

1-800-GO-VEXTA (468-3982)

ORIENTAL MOTOR U.S.A. Corp.

570 Alaska Avenue

Torrance, CA 90503

1-800-GO-VEXTA (468-3982)

The RKII Series Stepper Motors are designed to provide high performance and energy savings. To achieve constant maximum torque output with lower heat generation and save energy, the motor losses have been substantially reduced allowing them to be operated for longer hours at high speed which is not possible with conventional stepper motors. For use with RKII Series AC Input Drivers.

| Items |

PKE564AC 2.36 in. (60 mm) PKE Series 5-Phase Stepper Motor (AC Input) Web Price $97.00

|

PKE566AC 2.36 in. (60 mm) PKE Series 5-Phase Stepper Motor (AC Input) Web Price $102.00

|

PKE569AC 2.36 in. (60 mm) PKE Series 5-Phase Stepper Motor (AC Input) Web Price $109.00

|

PKE564AC-HS50 2.36 in. (60 mm) PKE Series 5-Phase Harmonic Gear Stepper Motor (Gear Ratio: 50:1) (AC Input) Web Price $1,206.00

|

PKE564AC-HS100 2.36 in. (60 mm) PKE Series 5-Phase Harmonic Gear Stepper Motor (Gear Ratio: 100:1) (AC Input) Web Price $1,206.00

|

|||||

| Frame Size | - 2.36 in | |||||||||

| Motor Length | - 1.91 in. | - 2.34 in. | - 3.50 in. | - 1.91 in. | - 1.91 in. | |||||

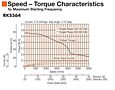

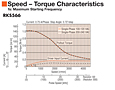

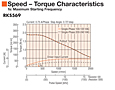

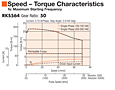

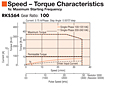

| Speed-Torque Characteristics |

-

|

-

|

-

|

-

|

-

|

|||||

| Holding Torque | - 73 oz-in | - 136 oz-in | - 250 oz-in | - 976 oz-in | - 1408 oz-in | |||||

| Type | - Standard | - Standard | - Standard | - Geared | - Geared | |||||

| Shaft/Gear Type | - Round Shaft with Flat (No Gearhead) | - Round Shaft with Flat (No Gearhead) | - Round Shaft with Flat (No Gearhead) | - Harmonic Gear | - Harmonic Gear | |||||

| Gear Ratio (X:1) | - | - | - | - 50 :1 | - 100 :1 | |||||

| Cable Direction | - | |||||||||

| Backlash | - | |||||||||

| Encoder Resolution | - | |||||||||

| Shaft | - Single | |||||||||

| Electromagnetic Brake | - Not Equipped | |||||||||

| Current | - 0.75 A | |||||||||

| Step Angle | - 0.72 ° | - 0.72 ° | - 0.72 ° | - 0.0144 ° | - 0.0072 ° | |||||

| Permissible Speed Range (r/min) | - | - | - | - 0 ~ 70 | - 0 ~ 35 | |||||

| Rotor Inertia | - 0.88 oz-in² | - 1.48 oz-in² | - 3 oz-in² | - 1.07 oz-in² | - 1.07 oz-in² | |||||

| Lost Motion | - | - | - | - 0.7 arc min maximum | - 0.7 arc min maximum | |||||

| Permissible Overhung Load | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 66 lb | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 66 lb | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 66 lb | - 0 in. from Shaft End = 72 lb0.2 in. from Shaft End = 83 lb0.39 in. from Shaft End = 99 lb0.59 in. from Shaft End = 123 lb0.79 in. from Shaft End = 162 lb | - 0 in. from Shaft End = 72 lb0.2 in. from Shaft End = 83 lb0.39 in. from Shaft End = 99 lb0.59 in. from Shaft End = 123 lb0.79 in. from Shaft End = 162 lb | |||||

| Permissible Thrust Load | - 1.55 lb | - 1.98 lb | - 3 lb | - 101 lb | - 101 lb | |||||

| Permissible Moment Load | - | |||||||||

| Safety Standards | - UL CE | |||||||||

|

|

||||||||||