Product Line

|

-

VEXTA®

|

Motor Type

|

-

Closed Loop

|

Frame Size

|

-

1.65 in

|

Motor Length

|

-

3.76 in.

|

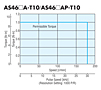

Speed-Torque Characteristics

|

-

Speed - Torque Characteristics

|

Holding Torque

|

-

140.8 oz-in

|

Type

|

-

Standard

|

Shaft/Gear Type

|

-

Taper Hobbed Gear

|

Gear Ratio (X:1)

|

-

10 :1

|

Backlash

|

-

10 arc min (0.167º)

|

Feedback Device (Motor)

|

-

Resolver

|

Electromagnetic Brake

|

-

Not Equipped

|

Shaft

|

-

Single

|

Power Supply

|

-

Single-Phase 100-115 VAC

|

Current

|

-

3.3 A

|

Resolution

|

-

0.036 °

|

Resolution Setting: 1000 P/R

|

-

0.036 °/Pulse

|

Permissible Speed Range (r/min)

|

-

0 ~ 180

|

Rotor Inertia

|

-

0.37 oz-in²

|

RoHS Compliant

|

-

Yes

|

Safety Standards

|

-

UL CSA (driver only) EN CE

|

CE Marking

|

-

Low Voltage Directives EMC Directives

|

Insulation Resistance

|

-

[Driver] 100 MΩ when measured by a 500 VDC megger between the frame-power supply input terminal and I/O-Power supply input terminal. [Motor] 100 MΩ minimum when measured by a 500 VDC megger between the frame-windings.

|

Insulation Class

|

-

[Motor] Class B (266ºF [130ºC]), UL/CSA: Recognized as Class A 221ºF (105ºC)

|

Dielectric Strength (Motor)

|

-

Sufficient to withstand the following for one minute: Frame-Windings 1.0 kV 50 or 60 Hz.

|

Dielectric Strength (Driver)

|

-

Sufficient to withstand for 1 min. - Frame-Power supply input terminal 1.5 kV 50 or 60 Hz, I/O-Power supply input terminal 1.8 kV 50 or 60 Hz

|

Ambient Temperature Range

|

-

[Driver] 32ºF ~ 104ºF (0ºC ~ 40ºC) [Motor] 32ºF ~ 122ºF (0ºC ~ 50ºC), nonfreezing

|

Ambient Humidity

|

-

85% or less (noncondensing)

|

Operating Atmosphere

|

-

No corrosive gases, dust, water or oil.

|

Components

|

-

ASD13B-AP (Driver) ASM46AA-T10 (Motor)

|

Shaft Runout

|

-

0.002 in. (0.05 mm) T.I.R.

|

Concentricity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Perpendicularity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Permissible Overhung Load

|

-

0 in. from Shaft End = 2.2 lb0.2 in. from Shaft End = 3.1 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 6.7 lb

|

Permissible Thrust Load

|

-

3.3 lb

|