ORIENTAL MOTOR U.S.A. Corp.

570 Alaska Avenue

Torrance, CA 90503

1-800-GO-VEXTA (468-3982)

ORIENTAL MOTOR U.S.A. Corp.

570 Alaska Avenue

Torrance, CA 90503

1-800-GO-VEXTA (468-3982)

| Items |

PK564AT IP65 Rated Step Motor Web Price Request Quote

|

PK566AT IP65 Rated Step Motor Web Price Request Quote

|

PK569AT IP65 Rated Step Motor Web Price Request Quote

|

PK564AE Stepper Motor Web Price Request Quote

|

PK564AE-H100S Stepper Motor with Harmonic Gear Web Price Request Quote

|

|||||

| Frame Size | - 2.36 in | |||||||||

| Motor Length | - 1.83 in. | - 2.26 in. | - 3.43 in. | - 1.83 in. | - 3.48 in. | |||||

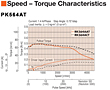

| Speed-Torque Characteristics |

-

Speed - Torque Characteristics |

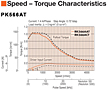

-

Speed - Torque Characteristics |

-

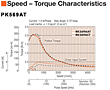

Speed - Torque Characteristics |

-

Speed-Torque Characteristics |

-

Speed - Torque Characteristics |

|||||

| Holding Torque | - 59 oz-in | - 117 oz-in | - 230 oz-in | - 59 oz-in | - 1120 oz-in | |||||

| Current per Phase (A/phase) | - 1.4 | |||||||||

| Type | - Standard | - Standard | - Standard | - Standard | - Geared | |||||

| Shaft/Gear Type | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Round Shaft (No Gearhead) | - Harmonic Gear | |||||

| Gear Ratio (X:1) | - | - | - | - | - 100 :1 | |||||

| Backlash | - | |||||||||

| Encoder Output | - | |||||||||

| Motor Connection Type | - Terminal Box | - Terminal Box | - Terminal Box | - Flying Leads | - Flying Leads | |||||

| Shaft | - Single | |||||||||

| Basic Step Angle | - 0.72º | |||||||||

| Output Step Angle | - 0.72 ° | - 0.72 ° | - 0.72 ° | - 0.72 ° | - 0.0072 ° | |||||

| Connection Type | - New Pentagon (Bipolar) | |||||||||

| Lead Wires | - 5 | |||||||||

| Rotor Inertia | - 0.96 oz-in² | - 1.53 oz-in² | - 3.1 oz-in² | - 0.96 oz-in² | - 1.15 oz-in² | |||||

| Lost Motion | - | - | - | - | - 0.7 arc min max. | |||||

| Static Friction Torque | - | |||||||||

| RoHS Compliant | - Yes | |||||||||

| Safety Standards | - UL CSA EN CE | |||||||||

| Radial Load | - 0 in. from Shaft End = 14.1 lb0.2 in. from Shaft End = 16.8 lb0.39 in. from Shaft End = 21 lb0.59 in. from Shaft End = 29 lb0.79 in. from Shaft End = 42 lb | - 0 in. from Shaft End = 14.1 lb0.2 in. from Shaft End = 16.8 lb0.39 in. from Shaft End = 21 lb0.59 in. from Shaft End = 29 lb0.79 in. from Shaft End = 42 lb | - 0 in. from Shaft End = 14.1 lb0.2 in. from Shaft End = 16.8 lb0.39 in. from Shaft End = 21 lb0.59 in. from Shaft End = 29 lb0.79 in. from Shaft End = 42 lb | - 0 in. from Shaft End = 14.1 lb0.2 in. from Shaft End = 16.8 lb0.39 in. from Shaft End = 21 lb0.59 in. from Shaft End = 29 lb0.79 in. from Shaft End = 42 lb | - 0 in. from Shaft End = 72 lb0.2 in. from Shaft End = 83 lb0.39 in. from Shaft End = 99 lb0.59 in. from Shaft End = 123 lb0.79 in. from Shaft End = 162 lb | |||||

| Axial Load | - 4.5 lb | - 4.5 lb | - 4.5 lb | - 4.5 lb | - 101 lb | |||||

|

|

||||||||||