Motores sin Escobillas

- Motores sin Escobillas Sistemas de Control de Velocidad CA

- Motores sin Escobillas Sistemas de Control de Velocidad CC

Atuadores Lineares

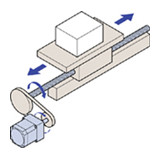

- Atuadores Lineares - Guías Lineales Motorizadas

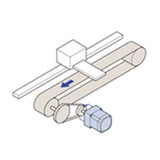

- Atuadores Lineares - Cilindros Lineales Motorizados

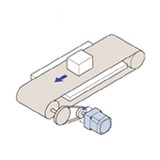

- Atuadores Lineares Compactos

- Atuadores Lineares (Actuadores Únicamente)

- Controladores / Productos de Red

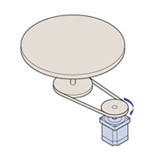

Actuadores Hiratorios Huecos

CAD / Búsqueda Manual

Para encontrar CAD y Manuales de Operador de nuestros products, por favor realice la búsqueda usando el número de item

![]()

Para Inglés o Español:

Para japonés:

Clientes de Mexíco:

Servicio Al Cliente - +001-847-871-5931

Soporte técnico - 800-681-5309

Clientes Internacionales:

+1-847-871-5931 o

+1-310-715-3304

Para soporte en productos del catálogo japonés:

1-800-746-6872 o

+1-310-715-3304

![]()

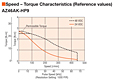

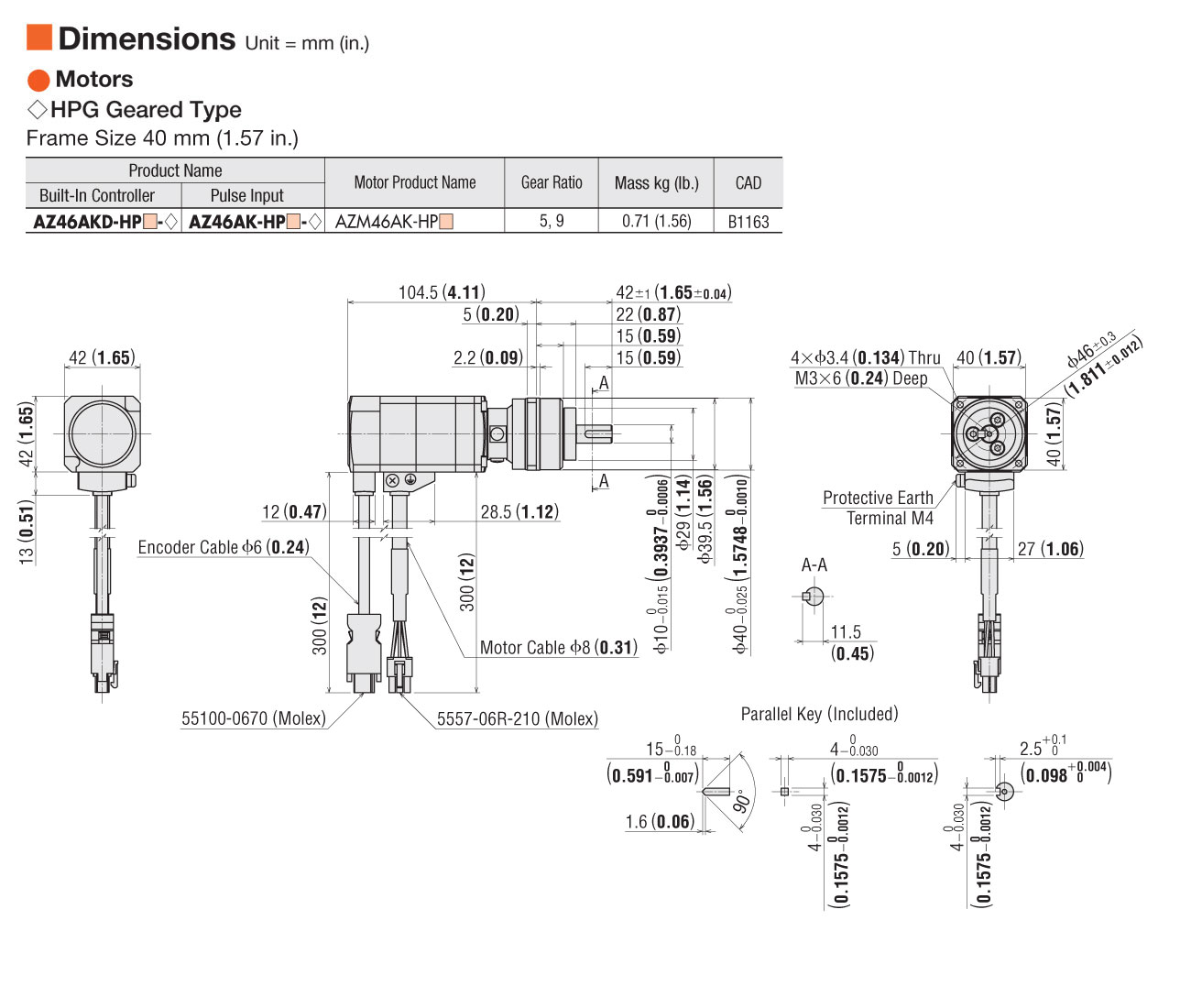

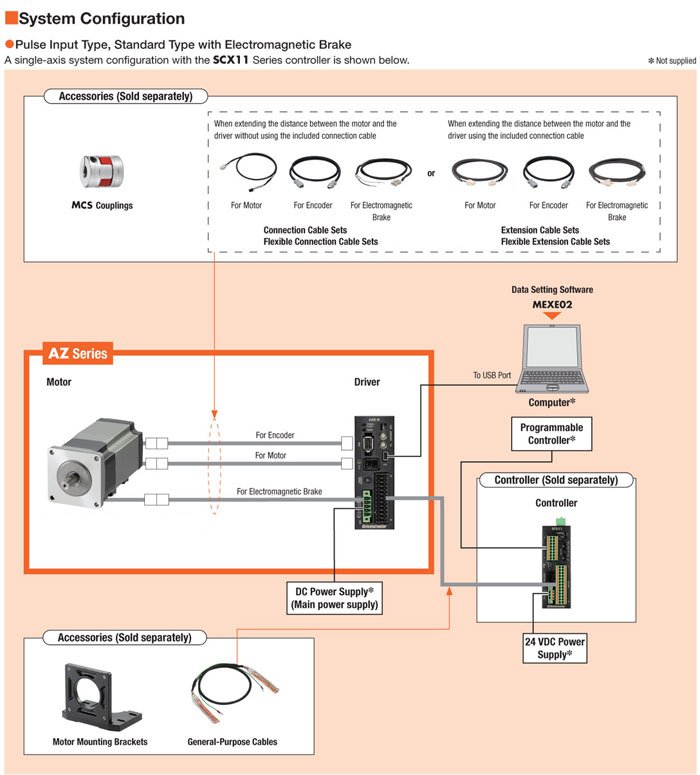

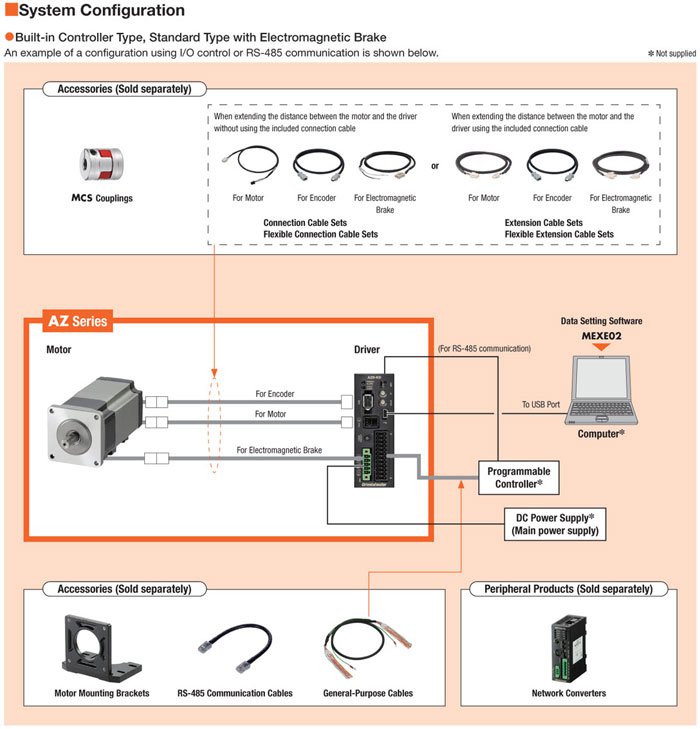

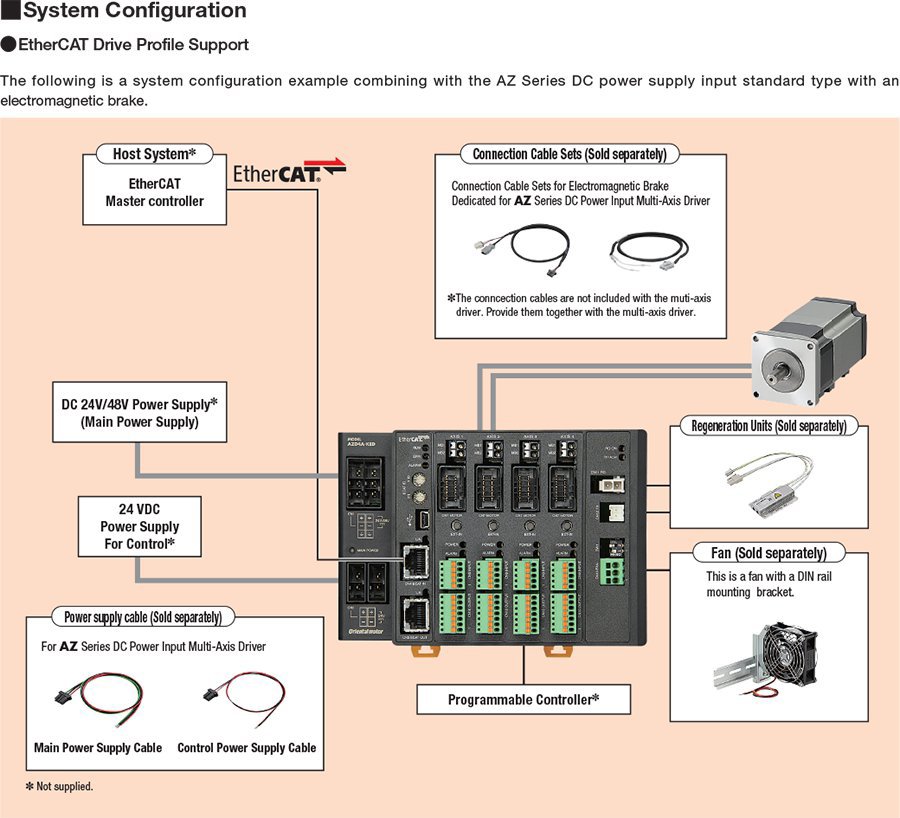

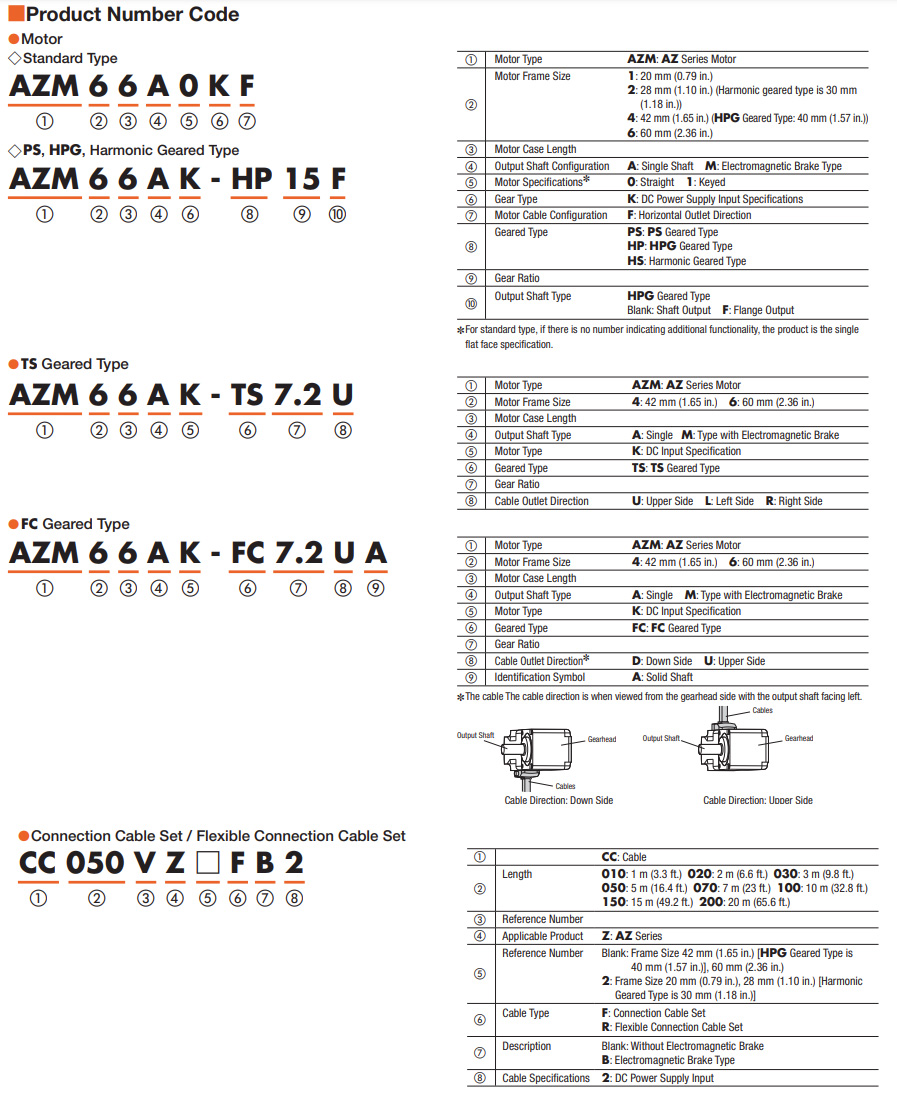

The αSTEP AZ Series stepper motor offers closed loop control, substantially reduces heat generation from the motor and by incorporating the newly developed Mechanical Absolute Encoder, absolute-type positioning is available, without battery back up or external sensors to buy.

- Requires αSTEP AZ Series Driver

*Connection Cables required (sold separately)

Compatible Motors

|

|

|

|

|

|

|

|

|

|

- 1 Quoted Ship Date for orders placed before 12:00 pm PST. Quantities may affect Shipping Date.