Product Line

|

-

Oriental Motor®

|

Motor Type

|

-

2-Phase Microstep

|

Frame Size

|

-

2.36 in60 mm

|

Motor Length

|

-

3.50 in.89 mm

|

Speed-Torque Characteristics

|

-

Speed - Torque Characteristics

|

Holding Torque

|

-

480 oz-in3.4 N·m

|

Type

|

-

Geared

|

Shaft/Gear Type

|

-

Planetary Gear

|

Gear Ratio (X:1)

|

-

5 :1

|

Backlash

|

-

10 arc min

|

Encoder

|

-

Not Equipped

|

Shaft

|

-

Single

|

Power Supply

|

-

20 ~ 40 VDC

|

Current

|

-

3.7 A

|

Basic Step Angle

|

-

0.36º

|

Permissible Speed Range (r/min)

|

-

0 ~ 360

|

Rotor Inertia

|

-

1.59 oz-in²290x10-7 kg·m²

|

RoHS Compliant

|

-

Yes

|

Components

|

-

RBD228A-K [Driver] PK266PDA-P5 [Motor]

|

Insulation Resistance

|

-

[Motor] 100 MΩ or more when 500 VDC megger is applied between the motor windings and the case under normal ambient temperature and humidity.

|

Dielectric Strength

|

-

[Motor] Sufficient to withstand 1.0 kVAC, at 50 or 60 Hz applied between the motor coils and casing for 1 min., under normal temperature and humidity.

|

Insulation Class

|

-

[Motor] Class B [266ºF (130ºC)]

|

Ambient Temperature Range

|

-

[Motor] 14 ~ 122ºF (-10 ~ 50ºC) (non-freezing) [Driver] 32 ~ 104ºF (0 ~ 40ºC) (non-freezing)

|

Ambient Humidity

|

-

85% or less (Non-Condensing)

|

Operating Atmosphere

|

-

Not exposed to corrosive gases, dust, water or oil.

|

Temperature Rise

|

-

Temperature rise of the windings is 144ºF (80ºC) or less measured by the change resistance method when equipped with an aluminum heat sink of 9.84 x 9.84 in., 0.39 in., thick. (at rated current, at standstill, 2 phases energized)

|

Shaft Runout

|

-

0.002 in (0.05 mm) T.I.R. at top of output shaft

|

Concentricity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Perpendicularity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Stop Position Accuracy

|

-

±5 arc minutes (±0.084º)

|

Radial Play

|

-

0.001 inch (0.025 mm) max. of 1.12 lb. (5 N)

|

Axial Play

|

-

0.003 in (0.075 mm) max. of 2.2 lb. (10 N)

|

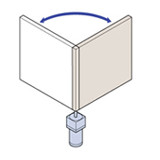

Radial Load

|

-

0 in. from Shaft End = 45 lb0.2 in. from Shaft End = 49 lb0.39 in. from Shaft End = 56 lb0.59 in. from Shaft End = 63 lb0.79 in. from Shaft End = 72 lb0 mm from Shaft End = 200 N5 mm from Shaft End = 220 N10 mm from Shaft End = 250 N15 mm from Shaft End = 280 N20 mm from Shaft End = 320 N

|

Axial Load

|

-

22 lb100 N

|

![]()