The AR Series stepper motor adopts our AlphaStep technology closed loop control so the motor does not lose synchronism even when subjected to abrupt load fluctuation or acceleration. Requires AlphaStep AR Series Driver.

| Items |

ARM66AK 2.36 in. (60 mm) AR Series Closed Loop Stepper Motor (DC Input) Web Price $232.00

|

ARM66AK-T3.6 2.36 in. (60 mm) AR Series Closed Loop Taper Hobbed Gear Stepper Motor (Gear Ratio: 3.6:1) (DC Input) Web Price $376.00

|

ARM66AK-T7.2 2.36 in. (60 mm) AR Series Closed Loop Taper Hobbed Gear Stepper Motor (Gear Ratio: 7.2:1) (DC Input) Web Price $376.00

|

ARM66AK-T10 2.36 in. (60 mm) AR Series Closed Loop Taper Hobbed Gear Stepper Motor (Gear Ratio: 10:1) (DC Input) Web Price $393.00

|

ARM66AK-T20 2.36 in. (60 mm) AR Series Closed Loop Taper Hobbed Gear Stepper Motor (Gear Ratio: 20:1) (DC Input) Web Price $393.00

|

|||||

| Frame Size | - 2.36 in60 mm | |||||||||

| Motor Length | - 2.54 in.64.5 mm | - 4.33 in.110 mm | - 4.33 in.110 mm | - 4.33 in.110 mm | - 4.33 in.110 mm | |||||

| Driver Voltage Input Power | - DC | |||||||||

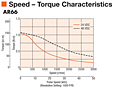

| Speed-Torque Characteristics |

-

Speed - Torque Characteristics |

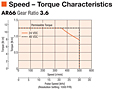

-

Speed - Torque Characteristics |

-

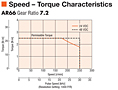

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

-

Speed - Torque Characteristics |

|||||

|

Holding Torque

|

- 142 oz-in1 N·m | - 176 oz-in1.25 N·m | - 352 oz-in2.5 N·m | - 416 oz-in3 N·m | - 480 oz-in3.5 N·m | |||||

| Shaft/Gear Type | - Round Shaft with Flat (No Gearhead) | - Taper Hobbed Gear | - Taper Hobbed Gear | - Taper Hobbed Gear | - Taper Hobbed Gear | |||||

| Gear Ratio (X:1) | - | - 3.6 :1 | - 7.2 :1 | - 10 :1 | - 20 :1 | |||||

| Backlash | - | - 35 arc min (0.584°) | - 15 arc min (0.25°) | - 15 arc min (0.25°) | - 10 arc min (0.167°) | |||||

| Lost Motion | - | |||||||||

| Shaft | - Single | |||||||||

| Electromagnetic Brake | - Not Equipped | |||||||||

| Permissible Speed Range (r/min) | - | - 0 ~ 500 | - 0 ~ 250 | - 0 ~ 180 | - 0 ~ 90 | |||||

| Rotor Inertia | - 2.1 oz-in²380x10-7 kg·m² | |||||||||

| Permissible Overhung Load | - 0 in. from Shaft End = 20 lb0.2 in. from Shaft End = 22 lb0.39 in. from Shaft End = 29 lb0.59 in. from Shaft End = 40 lb0.79 in. from Shaft End = 60 lb0 mm from Shaft End = 90 N5 mm from Shaft End = 100 N10 mm from Shaft End = 130 N15 mm from Shaft End = 180 N20 mm from Shaft End = 270 N | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb0 mm from Shaft End = 70 N5 mm from Shaft End = 80 N10 mm from Shaft End = 100 N15 mm from Shaft End = 120 N20 mm from Shaft End = 150 N | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb0 mm from Shaft End = 70 N5 mm from Shaft End = 80 N10 mm from Shaft End = 100 N15 mm from Shaft End = 120 N20 mm from Shaft End = 150 N | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb0 mm from Shaft End = 70 N5 mm from Shaft End = 80 N10 mm from Shaft End = 100 N15 mm from Shaft End = 120 N20 mm from Shaft End = 150 N | - 0 in. from Shaft End = 15.7 lb0.2 in. from Shaft End = 18 lb0.39 in. from Shaft End = 22 lb0.59 in. from Shaft End = 27 lb0.79 in. from Shaft End = 33 lb0 mm from Shaft End = 70 N5 mm from Shaft End = 80 N10 mm from Shaft End = 100 N15 mm from Shaft End = 120 N20 mm from Shaft End = 150 N | |||||

| Permissible Thrust Load | - 1.98 lb8.80 N | - 9 lb40 N | - 9 lb40 N | - 9 lb40 N | - 9 lb40 N | |||||

| Permissible Thrust Load | - | |||||||||

|

RoHS Compliant

|

- These products do not contain substances that exceed the regulation values in the RoHS Directive. | |||||||||

|

Safety Standards

|

- UL CE | |||||||||

|

|

||||||||||