|

Lead Time1

|

-

Contact you local saless office for more information

|

Return Policy

|

-

This product cannot be cancelled or returned once the order has been processed.

|

Frame Size

|

-

1.1 in

|

Motor Length

|

-

2.26 in.

|

Basic Step Angle

|

-

0.72º

|

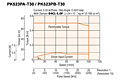

Speed-Torque Characteristics

|

-

Speed-Torque Characteristics

|

Holding Torque

|

-

71 oz-in

|

Current per Phase

|

-

0.35 A/phase

|

Type

|

-

Geared

|

Shaft/Gear Type

|

-

Taper Hobbed Gear

|

Gear Ratio (X:1)

|

-

30 :1

|

Gear Type

|

-

Taper Hobbed, Low Backlash (up to 45 arc min), Offset Shaft

|

Backlash

|

-

20 arc min (0.33º)

|

Motor Connection Type

|

-

Connector

|

Shaft

|

-

Double

|

Step Angle

|

-

0.024 °

|

Connection Type

|

-

New Pentagon (Bipolar)

|

Lead Wires

|

-

5

|

Rotor Inertia

|

-

0.049 oz-in²

|

RoHS Compliant

|

-

Yes

|

Safety Standards

|

-

UL CSA CE

|

Insulation Resistance

|

-

100 MΩ minimum under normal temperature and humidity, when measured by a 500 VDC megger between the windings and the motor casing.

|

Dielectric Strength

|

-

Sufficient to withstand 0.5 kV, 50 Hz or 60 Hz applied for one minute between the windings and casing, under normal temperature and humidity.

|

Temperature Rise

|

-

Temperature rise of the coil measured by the Change Resistance Method is 144ºF (80ºC) or less (at rated current, at standstill, five phases energized).

|

Insulation Class

|

-

Class B [266ºF (130ºC)], Recognized as Class A 221ºF (105ºC) by UL standard

|

Ambient Temperature Range

|

-

14ºF ~ 122ºF (-10ºC ~ 50ºC) (nonfreezing)

|

Ambient Humidity

|

-

85% or less (noncondensing)

|

Shaft Runout

|

-

0.002 in. (0.05 mm) T.I.R. at top of output shaft

|

Concentricity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Perpendicularity

|

-

0.003 in. (0.075 mm) T.I.R.

|

Radial Play

|

-

0.001 in. (0.025 mm) max. of 1.12 lb. (5 N)

|

Axial Play

|

-

0.003 in. (0.075 mm) max. of 2.2 lb. (10 N)

|

Radial Load

|

-

0 in. from Shaft End = 3.3 lb0.2 in. from Shaft End = 3.8 lb0.39 in. from Shaft End = 4.5 lb0.59 in. from Shaft End = 5.1 lb

|

Axial Load

|

-

2.2 lb

|