Busca de Manual e desenho 3D (CAD)

Para localizar o manual o desenho 3D (CAD) do produto digite o código do produto

![]()

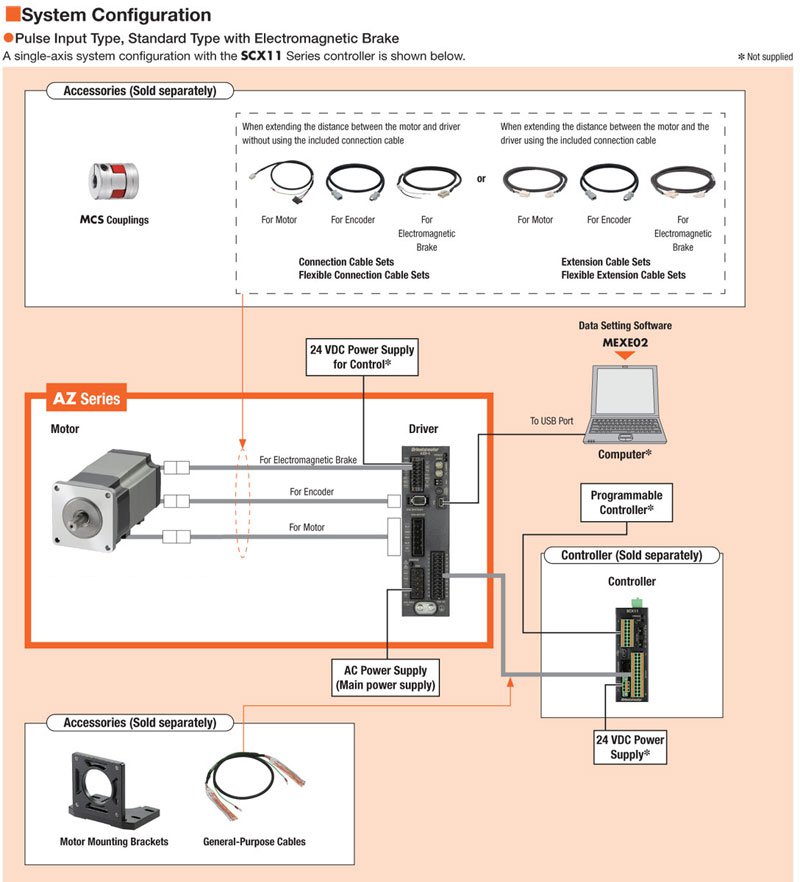

The αSTEP AZ Series stepper motor offers closed loop control, substantially reduces heat generation from the motor and by incorporating the newly developed Mechanical Absolute Encoder, absolute-type positioning is available, without battery back up or external sensors to buy.

- Requires αSTEP AZ Series Driver

*Connection Cables required (sold separately)

Compatible Motors

|

|

|

|

|

|

|

|

|

|

- 1 Quoted Ship Date for orders placed before 12:00 pm PST. Quantities may affect Shipping Date.